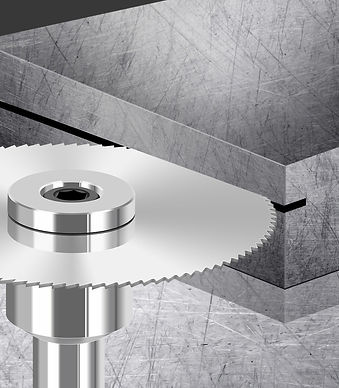

O que são Lâminas de serra circular de metal duro?

Lâminas de serra circular de metal duro sólido é feita de material de carboneto sólido (também chamado de "carboneto cimentado" ou "aço de tungstênio") como um todo, e é usada principalmente para produzir ranhuras e cortes de precisão com fresadoras CNC.

As lâminas de serra de corte de carboneto sólido são amplamente usadas na indústria de computadores, indústria eletrônica, indústria de motores elétricos, indústria têxtil, fabricação de máquinas-ferramentas e fabricação de ferramentas e assim por diante.

Por que carboneto?

Comparando com o material HSS, as lâminas de serra de metal de carboneto fornecem maior vida útil da ferramenta e tempos de ciclo reduzidos, também têm bom desempenho de alta dureza e longa vida útil, então as serras de corte de carboneto sólido podem atingir fresamento de alta velocidade e alta eficiência de processamento. As ranhuras fresadas são dimensionalmente precisas e têm um bom acabamento, resultando em alta qualidade do produto, podem ser amplamente utilizadas para fresamento e ranhuramento de madeira, cobre, alumínio e outros materiais difíceis de usinar, como aço comum, aço temperado, aço para rolamentos, aço inoxidável, liga de titânio, etc.

Que material pode ser cortado com Lâminas de serra circular de metal duro?

-

Alumínio e ligas de alumínio

-

Ligas de cobre, latão e bronze

-

Outras ligas de metais não ferrosos

-

Madeira/Plásticos não metálicos

-

Aço comum

-

Aço temperado

-

Ferro fundido

-

Liga de titânio

Lâminas de serra circular de metal duro série ToolingBox TC10/TC20

De acordo com diferentes aplicações, a ToolingBox pode fornecer lâminas de serra circular de carboneto sólido série TC10/TC20 com materiais de carboneto sólido para nossos clientes em muitas indústrias, incluindo marcenaria, máquinas, indústria leve, hardware, placa de circuito impresso, indústrias de vidro e assim por diante. A série TC10 é projetada para corte de madeira/plástico e metais não ferrosos, e a série TC20 é projetada para corte de aço. Basta nos perguntar se você tiver alguma dúvida sobre nossos produtos de lâmina de corte.

Por que nós?

Quem somos

Somos apaixonados por oferecer aos clientes serras de corte sólidas de carboneto de alta qualidade, de matéria-prima a produtos finais e estamos comprometidos em ajudar a resolver os problemas ao entrar e grooving. Hoje, do que o ToolingBox se orgulha é que temos uma equipe profissional com 20 anos médios de trabalho. Ajudaremos você do design, produção, relembrando o aplicativo final.

WHY US?

As vantagens de nossas serras de corte de carboneto

Blanks de carboneto de alta qualidade

Fabricado com blanks de carboneto de alta qualidade, duráveis e com longa vida útil

Serrilhada afiada

O ângulo dos dentes é especialmente projetado e o processo de moagem torna os dentes mais afiados.

Acabamento em espelho duplo

A superfície da lâmina de serra é lisa dentro de uma pequena tolerância para manter a qualidade do corte e alta eficiência.

Várias opções de especificação

passo grosso e fino com polegadas e em tamanhos métricos, diferentes espessuras podem ser oferecidas

Caso de uso e aplicação de serras de corte de carboneto

1. Comparação de serras de corte HSS e carboneto

O caso mostra que ao cortar materiais abrasivos, como ferro fundido ou ligas de alumínio-silício (Si > 10%), a vida útil das serras de corte de carboneto pode atingir de 8 a 10 vezes a de uma lâmina de serra de corte equivalente em HSS, e o tempo do ciclo de usinagem também será reduzido para 1/4 daquele das serras de corte HSS.

2. Caso de uso de serra de corte de carboneto

O caso mostra que as serras de corte de carboneto da série ToolingBox TC20 podem atingir uma vida útil da ferramenta muito boa (aproximadamente 200 ranhuras) com uma velocidade de corte razoável (80 m/min) ao cortar a parte do eixo de aço-liga.

Etapas de seleção de serras de corte de carboneto

01

Selecione o diâmetro externo

Geralmente, o diâmetro externo é selecionado pela profundidade de corte (Tabela 1).

03

Determinar a espessura

Determinar a espessura da lâmina de serra de acordo com as necessidades de corte (Tabela 2)

02

Selecione o diâmetro interno

Encontre o furo interno correspondente de acordo com o diâmetro externo (Tabela 2)

04

Passo grosso ou fino?

Se você estiver trabalhando com metais não ferrosos, a ToolingBox sugere uma serra de passo grosso e serras de passo mais fino para metais ferrosos.

*Dia Sizes larger than 100mm need to be customized!

Tooth Forms and Tooth Geometry:

Tooth form A with face similar DIN 1837 (fine teeth) ;

For low cutting depths, slots and thin-walled tubes with small diameter and for short broken chips.

Tooth form B with face similar DIN 1838 (large teeth) ;

For solid material, deep cuts, tubes with wall thickness above 2,5 mm and long broken chips.

Entre em contato conosco diretamente para obter um orçamento para consulta B2B ou vendas no atacado